A ghost from the past started

A few weeks back I was in the process of re-organizing my external hard drive. If you are like me, you have one of those external discs where you keep all your "work stuff." My disc literally contains my entire professional life work.

Sometimes I am amazed by the stuff that

So, I decided to organize my hard drive with these objectives in mind:

- To get rid of the stuff that does not help me anymore

- To establish a structure that makes sense no matter where I work (or for whom!)

- To find what I am looking for in the shortest time

One folder containing quite a few megabytes is labeled "Investigations." There I keep lessons learned, technical and safety alerts and investigation reports from my former teams.

The folder sadly has documents from each and every single district I have worked.

A Safety instructor once told me, "company standards are written in blood." Today I understand what he meant. Standards trail behind failures and accidents, and organizations and governments try to prevent their re-occurrence.

While organizing this folder, I realized that grouping the investigations by their topic instead of "by district" serves me far better in my current role as a well integrity "expert".

Where the events took place is no longer relevant for me. The important thing is what those investigations addressed, so I can show young engineers how to deal with certain well situations, and how to prevent the occurrence of similar events.

Reading tip: Free water in Cement: Why is it critical?

When I focused on the investigations related to service delivery who had caused downtime or other types of "red money" (wasted money), the one ghost that chased me from everywhere I have worked was "The Failure of cement plugs".

It is embarrassing how the reports reveal that the same mistakes are made over and over again in places as distant as Cabinda, Angola and Offshore Guyana, South America.

Free guide: The most common causes for leaks in oil wells and 8 questions to consider before you select solution.

To stop the feeling of shame, I will give you a quick summary of the more common causes of job failures when setting a cement plug:

-

Length, insufficient cement slurry volume

Operators that opt for saving money on slurry volume end up spending far more on rig time due to job repetitions. Plugs of less than 500 ft or less than 20 bbls of slurry are susceptible to fail. -

Slurry contamination due:

- Inadequate base to set the plug

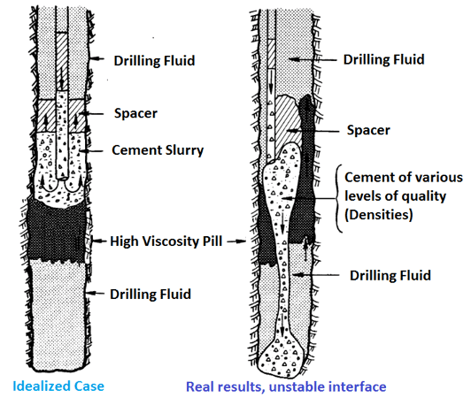

Poor viscous pill design or no use of pills to support plugs placed off bottom. The density of the cement will force it to go downhole as shown in the picture below. Make sure you design a pill capable of supporting the slurry on top of it.

- Slurry contaminated during placement

Fluids get intermixed when there are no physical barriers to separate them inside large drill pipes. - Slurry jetting into the viscous pill

The slurry, due to its weight, and assisted by gravity and the pump pressure, tend to jet into the viscous pill. Diversion in the annulus to force an upward flow is required to reduce the volume of slurry "lost" into the pill and on the bottom of the hole. - Inadequate fluid displacement techniques

Frictions in the wellbore caused by displacing fluids must exceed those of the fluids being displaced. That is why reviewing fluid properties is necessary. Hole geometry must be known to allow proper displacement. Sections of the hole with adequate size must be chosen to place the plug. - Use of drill strings with large tool boxes that disturb the plug when the string is pulled out of the hole.

- Reversing too close to the top of the cement will cause contamination due to jetting of the displacement fluid into the cement matrix.

- Inadequate base to set the plug

-

Excessive slurry thickening time

The longer the slurry remains fluid, the bigger the chances of the slurry getting contaminated. -

Poor quality control of slurry density before pumping

Mostly due to the use of non-pressurized mud balances.

-

No control of displacement volumes

Due to the use of rig pumps or no use of cement truck displacement tanks. -

Inadequate waiting-on-cement times

Anxious drillers that run and tag or attempt to drill out too soon.

The guidelines attached to this article (see also below) reveals more details on the reasons behind these failures and suggests how you ensure a successful cement job.

If you follow them, I am certain that your chances of getting it right the first time will increase significantly.

Best of Luck!

PS: If you have additional recommendations let us know in the comments field below, we will be glad to add them up and comment.

Recommended reading: